Tour Our Plant

Main factory floor.

Main factory floor.

The first process step for all gears and camshafts is turning.

The first process step for all gears and camshafts is turning.

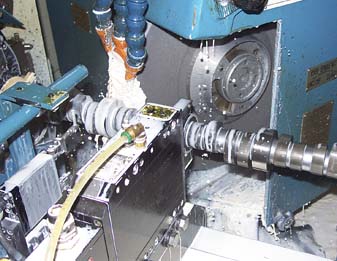

This Mazak Multiplex is a fully automated CNC turning center with a loader and un-loader.

Mazak CNC vertical milling center used for extremely accurate keyway milling and other high precision milling operations.

Mazak CNC vertical milling center used for extremely accurate keyway milling and other high precision milling operations.

Gear teeth for transmission gears and camshaft parts are produces on this CNC gear shaper and hobbing centers not shown.

Gear teeth for transmission gears and camshaft parts are produces on this CNC gear shaper and hobbing centers not shown.

CNC angle head machines can grind multiple diameters in one setup and hold tolerances of .0003 inches(.0079mm) on a diameter. Grinding is one of the last steps in the gear and camshaft manufacturing process.

CNC angle head machines can grind multiple diameters in one setup and hold tolerances of .0003 inches(.0079mm) on a diameter. Grinding is one of the last steps in the gear and camshaft manufacturing process.

Andrews Products has several CNC Landis camshaft grinders capable of processing parts up to 48 inches long and 4 inches in diameter. Landis grinders are best in class delivering superior accuracy and repeatability on complex parts.

Andrews Products has several CNC Landis camshaft grinders capable of processing parts up to 48 inches long and 4 inches in diameter. Landis grinders are best in class delivering superior accuracy and repeatability on complex parts.

CNC Hofler gear grinders are used to finalize exact gear tooth form.

CNC Hofler gear grinders are used to finalize exact gear tooth form.

Our metrology lab is temperature controlled. To support in process checks the room contains Gleason CNC gear checkers and a Ziess CMM.

Our metrology lab is temperature controlled. To support in process checks the room contains Gleason CNC gear checkers and a Ziess CMM.